Introduction

‘Transformative Research’ – It all started with the well known pivotal report ‘Science – the Endless Frontier’ [1] commissioned by President Roosevelt nearly 75 years ago. The report – penned by electrical engineer Vannevar Bush – marks the beginning of modern science policy. The publication came in the aftermath of the second world war, and has ever since represented the focus shift in science towards measurable benefits to society. The shift has since been considered vital for the progress towards national goals in – among other fields – health.

In light of this, I explore the ethical minefield surrounding the surgical procedure known as human head transplantation (HHT), and argue that it will become an inevitable part of our future.

In the very beginning, the primary goal of HHT will be to save the life of patients with terminal disease but whose head and brain are healthy. A brain dead patient donates his healthy body, and a HHT procedure is carried out to produce one healthy individual by fusing the terminal ill’s head with the donor’s body. Effectively, it would provide a life-saving treatment for a multitude of conditions where no cure currently exists [3].

For over a century, head transplantation experiments have been conducted – starting with dogs in 1908 and extending to primates in the 1970s. In the last decades, we have seen many improvements in vascular surgery, immunisuppressive agents, and spinal cord recovery – and this seems now to have reignited the enthusiasm for potential HHTs.

Technical Challenges

The overall hurdle of the HHT procedure can be divided into five categories [3]: a) Vessel anastomosis, b) Immunosuppression, c) Spinal cord transection and fusion, d) Revascularization, neuroprotection, cerebral ischemia and e) Pain control. The first two have mostly been overcome in the context of humans, and regards a) joining blood vessels and b) the management of the immune response system to avoid transplant rejection. Item c) regards splitting and joining of spinal cord segments and is currently the main unexplored technical challenge in the human context. However, also item d) regarding restoration of blood flow after a halt is challenging given that the human procedure will be time consuming. Finally, e) regards pain management, and also represents unexplored theritory based on that all experiments so far only have been performed on mice and non-human primates.

Ethical Challenges

When Joseph Murray conducted the first human kidney transplant in 1954, many demonized him as playing god and violating the rules of both nature and the divine. About 10 years later also the first human heart transplant resulted in a simarly negative public reaction. In the past 50 years we have since mastered both hand and face transplants – and every time, the discussions leading up to the current frontier seems to have the same negative character.

But today, even the World Health Organization argues that transplantations promote health. Almost 114,000 people in the U.S. are currently on the waiting list for a lifesaving organ transplant – and another name is added to the national transplant waiting list every 10 minutes. Since 1988, over 700,000 transplants have occurred in the U.S. alone [9].

While we refer to the HHT procedure as a head transplantation, it is truly a body transplantation, in which a person’s head is receiving a new body organ. Why is this so different from a single organ transplantation? The central question seems to be how patients who emerge from such a life-changing procedure might react. How will it affect their identity? [5].

This brings us to a philosophical theritory, in which we question what really makes up the human self. What makes you you? [6] Say you get a terminal disease and need transplantation of your liver. The operation is successful and you continue your life. Suddenly, bad luck strikes again, and you need new kidneys. The operation is again successful and everything is fine for a while. But the bad luck continues and you subsequently receive a new heart, new lungs, new blood and new facial tissue with the help from a range of donors. Would you still be you despite the fact that most of your original physical body was gone?

Many people believe that the brain – or the memories it stores – is what makes you you. However, there is a certain thought experiment which seems to disrupt also this picture: if a hard copy of you including your memories was created, would the new you also be you?

Modern cognitive science states that our cognition is an embodied cognition. It suggests that the human body is indeed part of the formation of the human self. Thus, will the body recepient encounter huge difficulties in trying to adapt to the new body under his already existing body image? Could it lead to insanity and death? In face transplantation studies, however, identity confusion have so far not been reported. In fact – after face transplantation – the opposite has been noted in terms of increased self-esteem, easier social integration and better mental health [3].

The cause preventing HHT research to progress quicker than it currently does seems to rooted in a so called deadlock: to overcome the technical challenges, we need to do more experiments. But to do experiments we need subjects, and to get subjects we need to prove that what we are doing is safe. But to prove that – we again need clinical evidence from experiments.

Given the present regulatory environment, development of innovative and transformational surgery is difficult to accomplish because institutional review boards may not approve experiments in which suffering and death are likely. It may be possible to obtain an informed consent by a brain dead donor via his family, but it is forbidden by several Conventions (The Nuremberg Code, the Declaration of Helsinki, and The Belmont Report) to get consent for a dying person to a surgical experiment which has not followed standard protocols of research development [3].

The path leading up to successful HHT is indeed likely to involve suffering and death. But is this different from other human endeavours such as space exploration? As of 2018, 14 astronauts and 4 cosmonauts have lost their lives in fatal spaceflight accidents. Also while training for space missions astronauts have died, such as in the Apollo 1 fire where the entire crew of three burned to death on the launch pad. They were well informed about the risks involved, but chose to do it still. It seemingly does not hinder humanity from exploring space. Astronauts are astronauts for a reason, they choose to be what they are and are willing to take huge risks just because they see themselves as instruments dedicated to space exploration. Afterall, experimental surgical procedures with a high probability of suffering and death are not very different from sending a manned capsule filled with liquid hydrogen to the moon. Why should we forbid a terminally ill patient from undergoing an experimental surgery if he wants to do so for science? The main difference is that astronauts are healthy, while HHT body receipients are not. Therefore the act of experimentation is automatically considered coercive and vicious.

The HHT seems to touch on almost every aspect of any research ethics guideline (such as [2]): a) risk asscociation, b) the precautinonary principle, c) compliance with national and international rules and regulations, d) care and respect of animal welfare, e) the economic and cultural value of other forms of knowledge and f) openness about possible conflicts of interest.

Regarding a): Let us wipe the patient consent aside for the moment and assume it is acquired; is it still ethical for the actual physician to subject the patient to an experimental HHT procedure with a multitude of unknown variables awaiting the surgeons in the operating room? [4]

Regarding b) Assuming that the HHT procedure was carried out. Afterwards the patient experiences a fatal chronic rejection of the body, and all attempts to reverse rejection fails. The head must be removed from the body. What is now the exit strategy? [3]

Regarding c) Let us assume that the HHT procedure is successfully carried out. Later the patient experiences a radical self-esteem boost, and starts to socialize. He meets a wonderful girl, and they decide to get a baby. They name their little son Jack. As Jack grows older, he may pose questions about inheritance, parentage and custody. How will the parents of the body donor meet Jack as the offspring of their brain-dead child? [3].

Regarding d) On the path towards HHT, much more trials on animals will be required. All procedures must first be approved by the Animal Welfare and Ethics Research Committee [7]. Can it under any circumstance be ethically sound to perform such a substantial amount of pre-clinical experimentation on animals?

Regarding e) Should the medical community really consider HHT instead of focusing their efforts on more direct approaches towards curing ALS and similar debilitating diseases? [4]

Regarding f) In the context of utilitarianism, HHT can be considered very ineffecient because one body can save only one life per HHT, but the same donor body could instead be used to save many lives through multiple organ donations [4].

Another argument against HHT is related to social hierarchies and the fear for a ‘black body market’: HHT surgery will indeed be very costly, and we can end up with an elite group of very rich people which regularly buy themselves new bodies and immortal life from people in the other far end of the class spectrum.

Conclusion

Many ethical questions regarding the HHT will remain unanswered until trials are performed on humans. This basically leaves us with the pressing question of pre-cautionarity. But if we use past experience as an indicator of ’the storm to come’, the history of organ transplantation is telling. The public reaction to the first organ transplant 50 years ago was initially not very positive.

But humankind inherently seems to be pushing ethical boundaries in parallel with technological boundaries. The HHT is the final frontier of organ transplantation because it represents the ultimate surgical challenge. On a large scale, the biggest challenges are what drives science. The most transformative research topics will always be tied to the largest challenges and the biggest ethical questions.

Although the Apollo moon program was in the days seen by many as a huge waste of resources, and considered unethical in terms of that money was spent ’out there’ instead of on the problems ’down here’ – it paved the way for an extraordinary sized array of technologies which has become relevant for almost every industry we have on earth today.

Under this vision – it seems to be only a matter of time before the relation to Frankenstein vanishes, and the phrase of getting a new summer body suddenly gets a whole new meaning. A time where we can read about the 465 years old President who now has successfully received his 7th new body – and is ready to serve the country in the coming century.

References

[1] SCIENCE – THE ENDLESS FRONTIER https://www.nsf.gov/od/lpa/nsf50/vbush1945.htm

[2] The NENT Guidelines for Research Ethics in Science and Technology

[3] Allen Furr and Mark A. Hardy and Juan P. Barret and John H. Barker Surgical, ethical, and psychosocial considerations in human head transplantation Int J Surg. 2017 May ; 41: 190?195.doi:10.1016/j.ijsu.2017.01.077. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC5490488/pdf/nihms863662.pdf

[4] Joshua A. Cuoco and John R. Davy Operation Frankenstein: Ethical Reflections of Human Head TransplantationNeurosurg. 2016, 1:2 http://neurosurgery.imedpub.com/operation-frankenstein-ethical-reflections-ofhuman-head-transplantation.pdf

[5] Nayan Lamba and Daniel Holsgrove and Marike L. Broekman The history of head transplantation: a review REVIEW ARTICLE – HISTORY OF NEUROSURGERY https://www.ncbi.nlm.nih.gov/pmc/articles/PMC5116034/pdf/701_2016_Article_2984.pdf

[6] Tim Urban What Makes You You? The Wait But Why Blog https://waitbutwhy.com/2014/12/what-makes-you-you.html

[7] Anto Cartolovni and Antonio G. Spagnolo Ethical considerations regarding head transplantation SURGICAL NEUROLOGY INTERNATIONAL: Letter to the Editor http://surgicalneurologyint.com/surgicalint-articles/ethical-considerations-regarding-head-transplantation/

[8] John H. Barker and Johannes M. Frank and Liudmila Leppik Head Transplantation: Editorial Commentary CNS Neuroscience and Therapeutics:Editorial Commentary https://onlinelibrary.wiley.com/doi/epdf/10.1111/cns.12434

[9] American Transplant Foundation Webpage https://www.americantransplantfoundation.org/about-transplant/facts-and-myths/

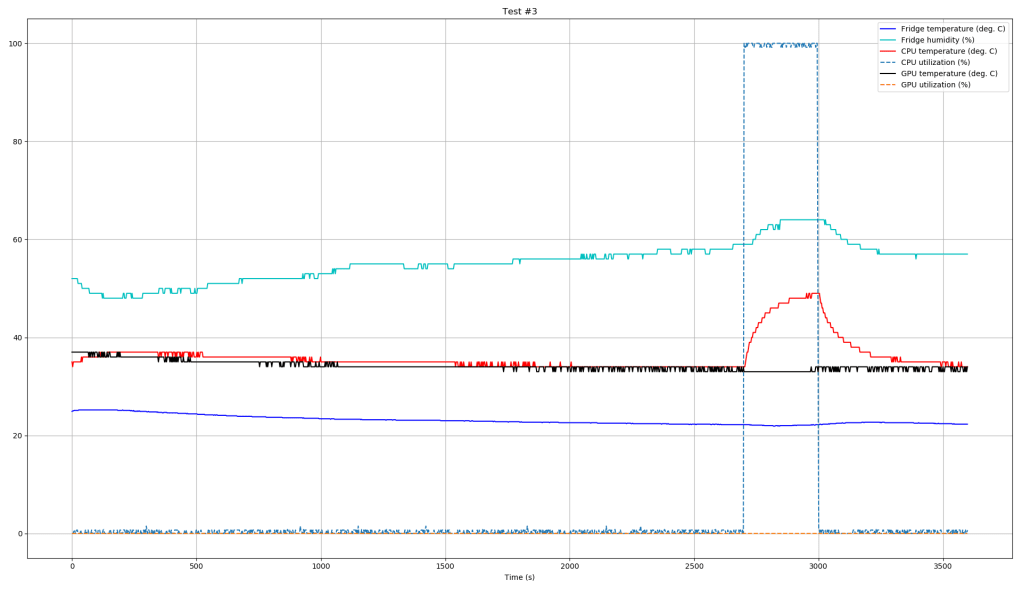

The computer fridge hypothesis is a seemingly brilliant idea: store and operate your computer in a fridge, and wave good bye to all heating issues.

The computer fridge hypothesis is a seemingly brilliant idea: store and operate your computer in a fridge, and wave good bye to all heating issues.

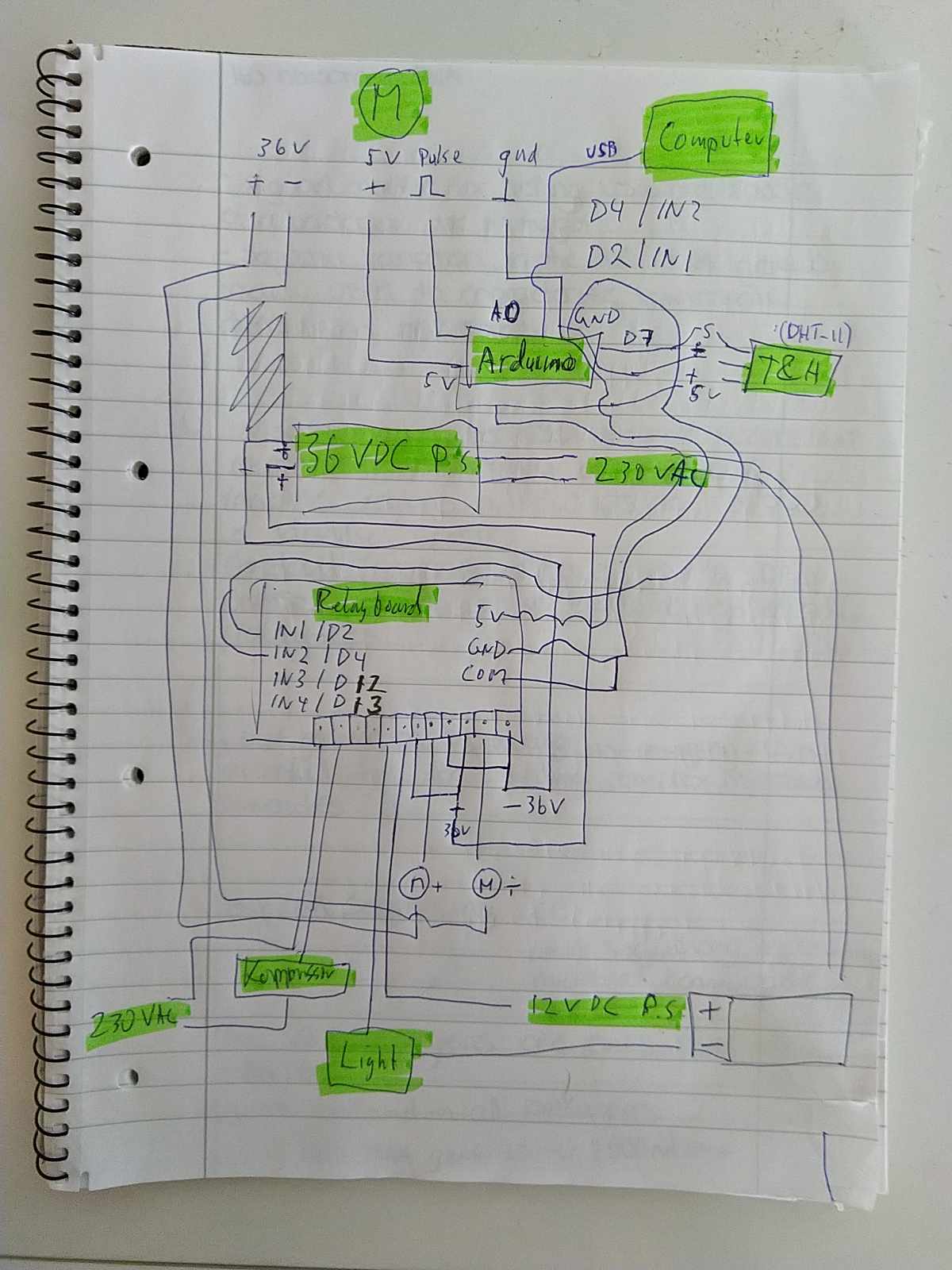

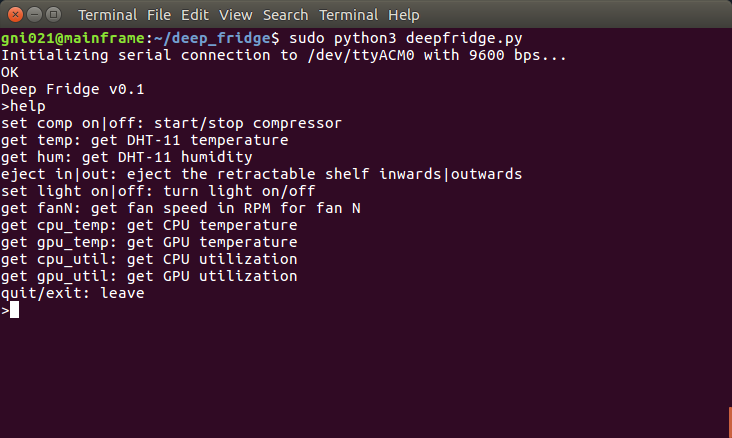

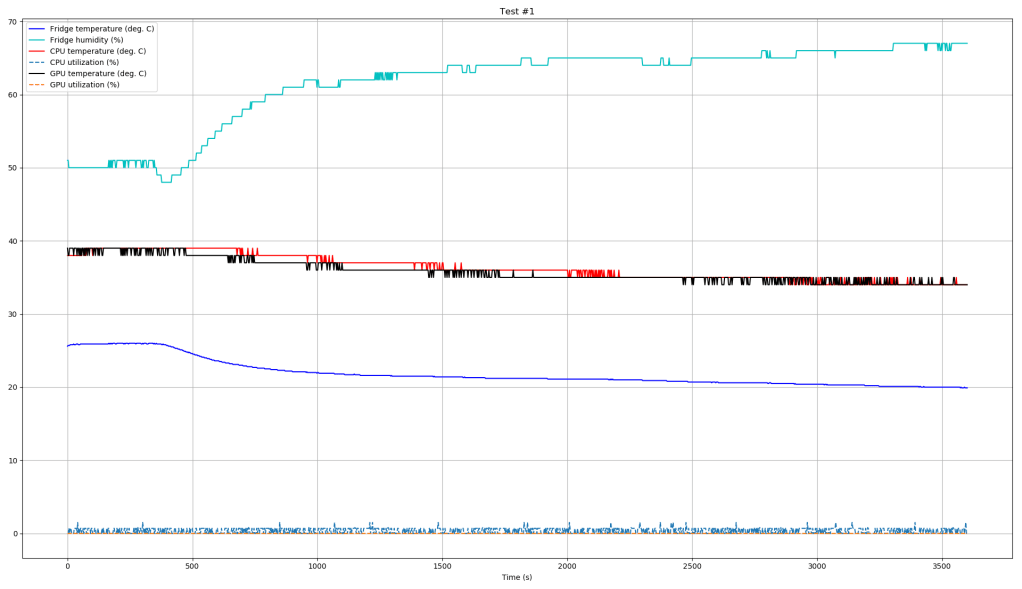

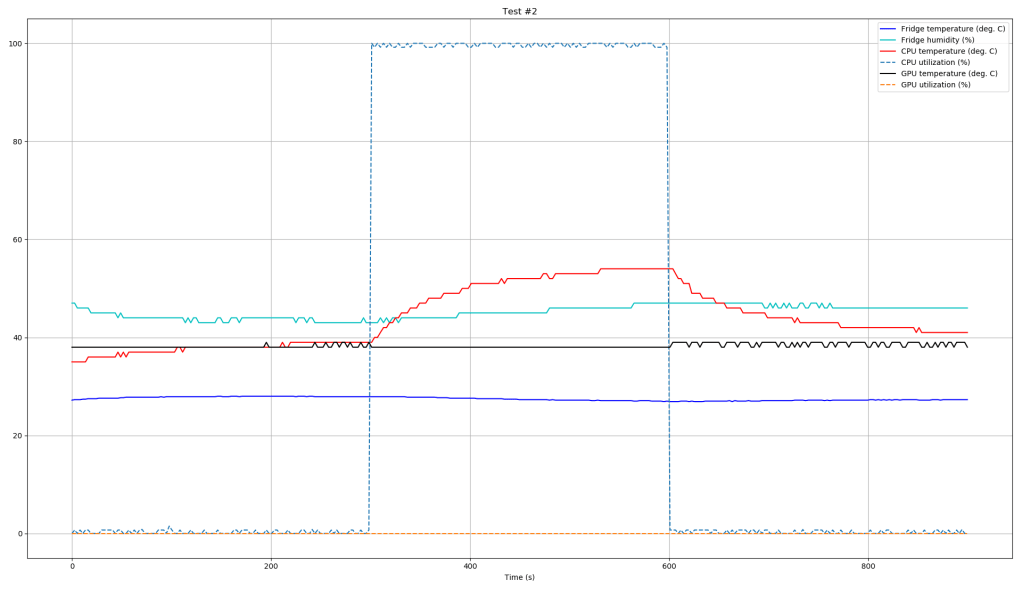

I decided to install a simple balanced ventilation system represented by four

I decided to install a simple balanced ventilation system represented by four